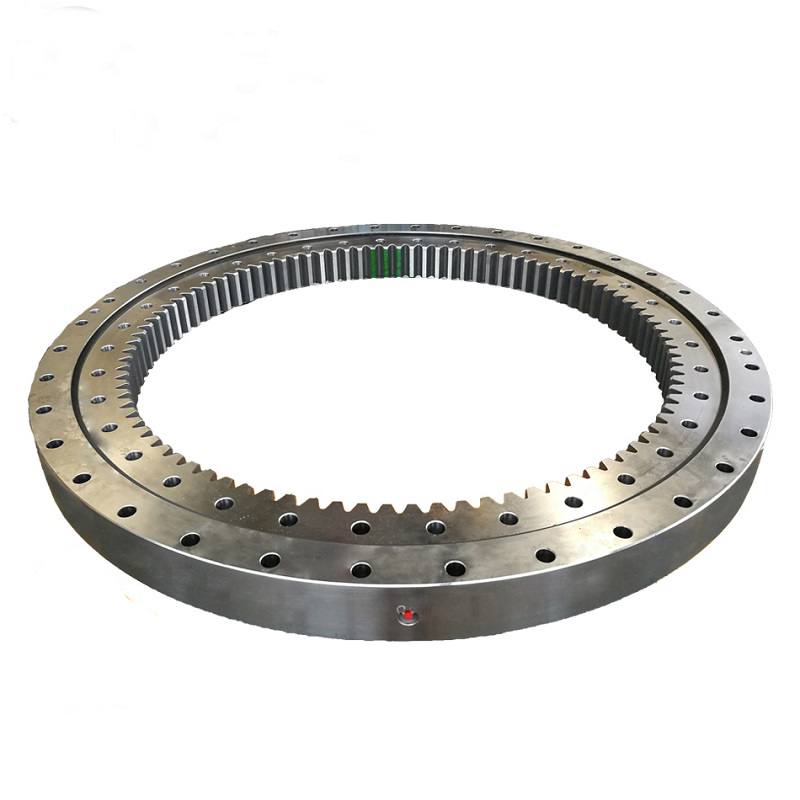

Internal Gear Slewing Bearing

Internal Gear Slewing Bearing

Internal gear slewing bearing offer a unique variation within the world of slewing bearings. Unlike traditional designs where the gear teeth are located on the outer diameter, internal gear bearings have the teeth machined onto the inner ring. This design provides several advantages for specific applications. The most notable benefit of an internal gear slewing bearing is its compact profile. By integrating the gear teeth within the inner ring, the overall diameter of the bearing is reduced. This space-saving feature is valuable in applications where size constraints are a concern, such as robotic arms or compact construction equipment. Design and constrcution: He defined the characteristic of this bearing type as the gear teeth machined directly onto the inner ring. This ring typically features a high-strength steel construction to handle the rotational forces transmitted through the gear teeth. The specific tooth profile (spur gear, helical gear, etc.) will depend on the application requirements.